Integrity analysis of small diameter pipes and connections

Small diameter pipes and connections represent a critical challenge in industrial asset management, commonly known as the "Small bore, big problem." These components are prone to fatigue failure due to vibrations, especially at connection points with geometric discontinuities.

Keep reading...

Consequence Assessment for the Management of Pipelines Near Inhabited Areas – A New Approach

This approach enhances risk management by integrating advanced simulations and meteorological data to accurately assess the impact of pipeline ruptures near populated areas. By considering variables such as wind direction and speed, this methodology identifies high-risk zones that might be overlooked in traditional analyses, enabling more effective mitigation strategies to protect both communities and critical infrastructure.

Keep reading...

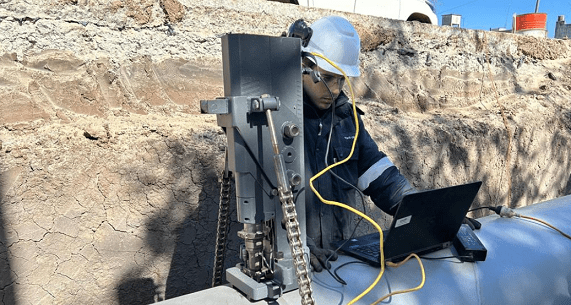

Geotechnical Instrumentation and Monitoring: Tailings Dam

A tailings dam is a mining infrastructure designed to recover water and store residual solids from mineral processing. Its integrity can be compromised by seepage or natural events, increasing the risk of rupture and associated damage. To mitigate these risks, piezometers and accelerometers are used to constantly monitor water levels and seismic activity. Learn more about this solution in the current interest note.

Keep reading...

Evolution and Advantages of Digital Radiography in the Oil & Gas Industry

Digital radiography has revolutionized the oil & gas industry by enhancing the quality of structural integrity inspections and defect detection. Its advantages include reducing radiation exposure time, eliminating chemicals, and the ability to digitally store and analyze images, which optimizes processes and contributes to safety and environmental sustainability.

Presentation of the New GIE GROUP Board

On May 22nd, the presentation ceremony of the new Board and the transfer of the presidential mandate from Engineer @Mauricio Teutónico to Geologist @Gustavo Martinez took place at the Mar del Plata headquarters.

Keep reading...

Instrumented Indentation: 15 years of experience providing know-how and technical support to the industry.

In 2008, we developed the instrumented indenter ESYS 10 with state support, allowing the industry to evaluate mechanical properties of materials without destructive testing. Over 15 years, only five companies worldwide offer this service, with GIE GROUP standing out in Argentina and Latin America. Learn more about its features in the following article.