Value proposal

We help those responsible for maintenance and industrial operations to identify the main equipment that generates unplanned production interruptions, and to define the necessary actions to reduce maintenance costs, maximize the availability and productivity of the installation.

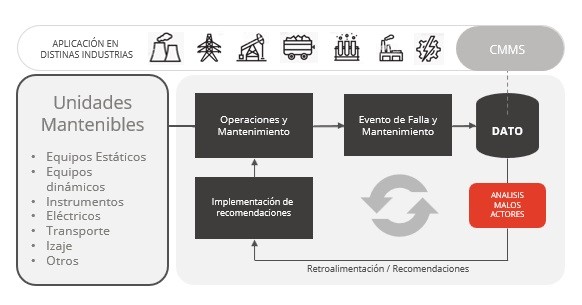

This service is aimed at multiple sectors such as Food Sector, Mining, Oil & gas, Agroindustry, among others . The methodology can be applied to all those industries that have a CMMS (computerized maintenance management system) or keep a detailed maintenance record.

HIDDEN BAD ACTORS METODOLOGY