Determine the threats to your assets

Through Quantitative Risks Analysis, you will be able to analyze threats to pipeline or equipment integrity by calculating the probability of occurrence and the potential consequences of an event, determining risk through complex mathematical treatment. HAZOP - Hazard and Operability Study. It is a systematic risk-assessment technique to identify hazards and problems that could impede an efficient operation of industrial facilities. Through the Development and Analysis of Qualitative Risks, you will be able to analyze results in the identification of dangerous segments and the indexes that impact on those segments.

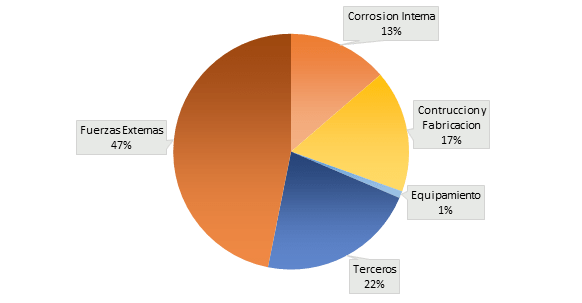

QRA Risk Example in GIS