Why perform in line inspections?

In Line Inspection (ILI) comprehends the assessment of pipelines through nondestructive techniques and tools in order to detect and measure inner damage. IL Inspection enables to issue reports about irregularities in pipelines, including corrosion, cracks, deformations or other defects. IL Inspections are commonly performed in the Oil&Gas Industry, especially in long stretches of pipelines. Information gathered from ILI is vital for asset management. GIE Group guarantees reliability throughout the ILI analysis, from the design of the solution to the analysis of data

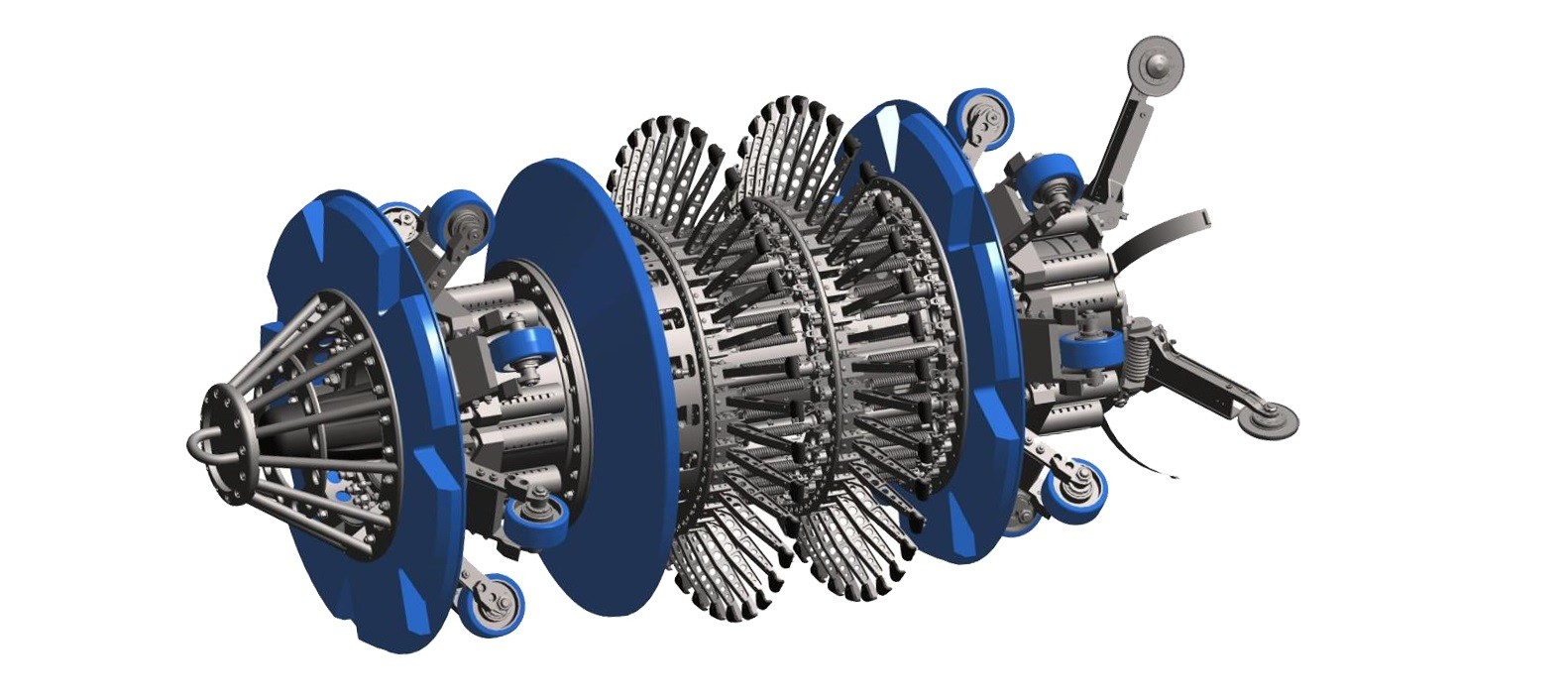

In-line inspection tools