IOW – INTEGRITY OPERATING WINDOWS

IOWs identify safe operation limits in order to avoid degradation and lost of primary contention in equipment. The ultimate purpose of IOWs is to reduce operating risks in process equipment.

IOWs is a Methodology to set boundaries in process variables in order to prevent material degradation caused by deviation from process parameters in equipment under pressure. This methodology is based on the recommended practice by API RP 584

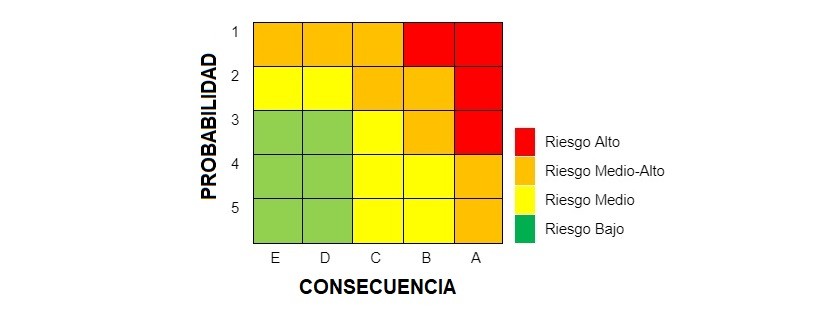

PROBABILITY AND CONSEQUENCE SCALE IN IOW METHODOLOGY