Electromagnetic Inspection Technology

This latest generation technology is used during the inspection of assets as those found in oil refineries or chemical plants, splash zones or underwater facilities (off-shore platforms, ships or docks).

It is also used for underwater pipelines, structural steel and ammonia refrigeration systems, corrosion under insulation (CUI), corrosion under coating, flow assisted corrosion and superficial corrosion

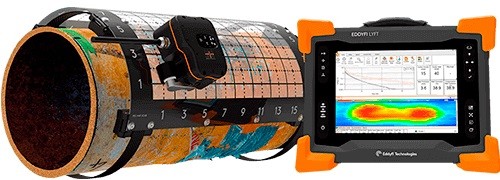

PEC - Pulsed Eddy Current Equipment