Monitoring and Detection of Changes in Temperature, Deformations and Vibrations

We help integrity, maintenance, and operations managers in the oil and gas and mining sectors monitor and detect changes in temperature, deformations, and vibrations that could affect the integrity of their assets and facilities. With this system, you'll have real-time, remote information about your assets. This will increase safety and operational continuity, ensuring the safety of people and the environment.

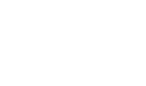

Fiber Optic Pipeline Monitoring