Cathodic Protection (CP) System Descriptions Features

Cathodic Protection (CP) systems are an important method for preventing corrosion in buried pipelines and an essential part of the Integrity System.

All operators must perform periodic measurements of the CP level reached. This requires periodic measurements at rectifiers and at specific test points along the entire line. The application of remote CP monitoring and supervision technologies in pipelines has proven to be a reliable and cost-effective means of monitoring the proper functioning of cathodic protection systems.

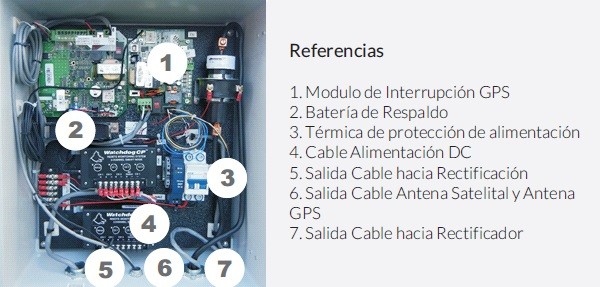

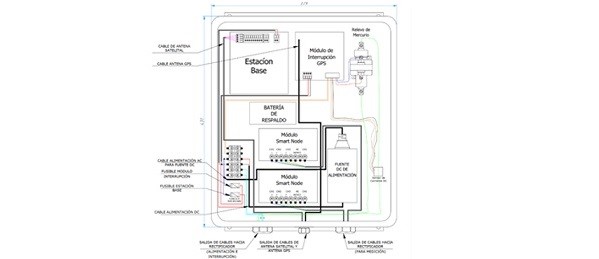

Remote Cathodic Protection System