Our Value Proposition

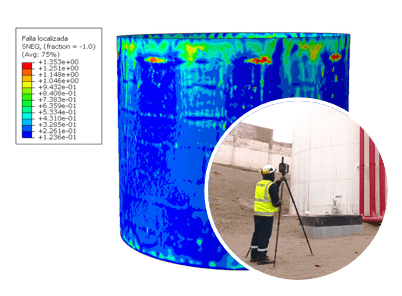

We help Integrity, Maintenance, and Reliability managers in the Oil & Gas, Mining, and Petrochemical sectors to evaluate and diagnose deformations, settlements, and geometrical alterations that may compromise the structural and operational integrity of their storage tanks.

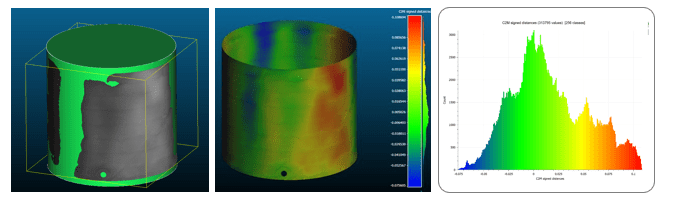

Through our integrated LiDAR scanning and finite element analysis solution, you will have a precise and complete assessment of your tanks' condition, complying with the most demanding international standards.

FFS - Fitness for Service || Storage Tanks