INTRODUCTION

Tailings dams, also known as TSF (Tailings Storage Facility), are containment structures used in the mining industry to safely store the waste with no economic value generated during the mineral concentration process. Their main function is to confine the material and promote the decantation of water, which can be later recovered and reused in the production process, thus optimizing the use of water resources.

The design of these structures must ensure their stability throughout their entire lifespan, considering the capacity to withstand static and dynamic loads, extreme hydrological events, and, in seismic zones, significant ground movements. Due to their nature and volume, a failure in a tailings dam can generate environmental, economic, and human consequences of great magnitude, which is why their permanent monitoring and the implementation of monitoring systems are essential for risk management and operational safety.

A dam’s monitoring system is the integrated set of instruments, sensors, and procedures intended to periodically or in real-time monitor the structural and geotechnical behavior of the dam during the construction, operation, and post-closure stages.

These systems allow for the measurement and recording of key variables such as pore pressures, deformations, displacements, vibrations, water table levels, and seismic accelerations, integrating the information into an analysis platform that facilitates early decision-making. Its main objective is to guarantee the stability and safety of the structure, prevent catastrophic failures, and comply with regulatory and risk management requirements.

In the case of the monitoring system for Dam D at the Porco Mine, owned by the Sinchi Wayra Mining Group, it originally had ten vibrating wire piezometers with manual measurement. This system was supplemented with the installation of seven new piezometers, two data acquisition systems based on dataloggers, and an accelerograph, in addition to the necessary power, protection, and communication systems.

All the data generated by the instrumentation, both from manual and automatic measurements, were integrated into the Gie Cloud platform for storage, visualization, and analysis.

DESCRIPTION OF THE IMPLEMENTED MONITORING SYSTEM

PIEZOMETERS

Vibrating wire piezometers are instruments designed to measure interstitial pressure (or pore pressure) in the constituent material of the dam or its foundation. In Dam D, these sensors installed on the slopes help to assess its stability, given that an increase in pore pressure reduces the effective strength of the material, increasing the risk of instability or liquefaction.

The installation was carried out according to the traditional installation method, which consists of drilling to a depth slightly greater than required and forming a sand collection zone where the piezometer is placed, then installing a bentonite seal and filling the rest with a bentonite-cement grout. The cables were laid in a trench to huts at each end where the acquisition, power, and communication system was installed.

Figure 1. Piezometer hut equipment

ACCELEROGRAPH

The accelerograph is an instrument capable of recording accelerations on three axes (longitudinal, transverse, and vertical). In Dam D, it is installed on the crest, where the maximum dynamic stresses are recorded.

Its main function is to activate inspection and control protocols in case of recording a seismic event that exceeds predefined acceleration thresholds that could have generated structural damage.

The installation was carried out on a concrete pad on the crest of the dam, ensuring firm contact with the structure for precise transmission of accelerations. The equipment was integrated into the power and communication system of its own hut.

Figure 2. Accelerograph hut equipment

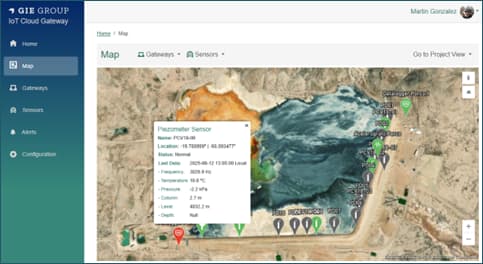

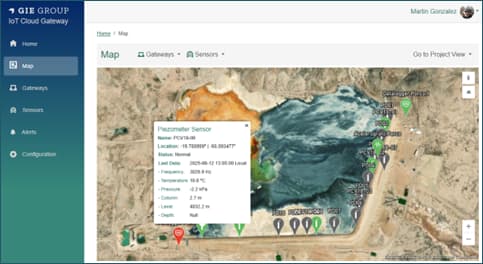

INTEGRATION WITH GIE CLOUD

Gie Cloud is an IoT platform for the management, storage, visualization, and analysis of data from various monitoring systems. Its objective is to centralize and unify the information captured by different sensors and instruments, allowing it to be consulted in real-time or historically from a secure web environment.

In the case of monitoring systems, Gie Cloud acts as a centralized repository where data from:

- Piezometers (pore pressures, water table level).

- Accelerographs (seismic accelerations and vibrations).

- Other instruments such as inclinometers, weather stations, or displacement meters.

Its main functionalities include:

- Secure data storage in the cloud, with backup and redundancy.

- Graphical visualization of time series, trends, and comparisons.

- Generation of automatic reports and data export.

- Management of alarms and configurable thresholds for early detection of critical conditions.

- Multi-user access with different permission levels.

A wireless network was implemented at the dam that links all the instrumentation huts, providing connectivity to the cloud through a cellular modem. The Gie Cloud platform was deployed in conjunction with an OpenVPN server, which allows remote access to the equipment for maintenance and/or update tasks.

Figure 3. Integration with the Gie Cloud platform

The dataloggers transmit the frequency and temperature data recorded by the piezometers daily via MQTT protocol, from which the platform calculates the pressure and piezometric head values.

The accelerograph is checked every 15 minutes for new recorded events, which are subsequently uploaded to the platform.

Additionally, the solar panel power and battery voltage parameters are supervised every hour, allowing for the control of the system’s energy status.

Figure 4. Georeferenced instrumentation view

Figure 5. Accelerograph events

Figure 6. Datalogger operation data

The Gie Cloud alert system automatically notifies users by email when any instrument parameter exceeds the established alert levels. In the case of the accelerograph, in addition to the notice, the file corresponding to the new detected event is attached, facilitating its immediate analysis.

This approach allows technical personnel to continuously supervise the dam’s behavior, both in the field and remotely, optimizing resources and reducing response times to any anomalous condition.

The real-time monitoring capability and the stored data history provide a solid basis for trend analysis, evaluation of the effectiveness of corrective measures, and updating of geotechnical models.

In this way, the communication and integration infrastructure with Gie Cloud ensures that the management of the dam’s stability is carried out with high standards of reliability and traceability.

CONCLUSION

The implementation of the monitoring system in Dam D at the Porco Mine, complemented by remote connectivity and centralized management in Gie Cloud, represents a significant advance in the surveillance of structural safety.

The combination of piezometers, an accelerograph, dataloggers, and an automated alert system provides a comprehensive tool for the early detection of risks, allowing for the adoption of preventive measures before conditions can compromise the stability of the dam.

Having a platform like GIECloud allows the user to centralize information from different types of sensors, from different providers, in a single place. Without this tool, the remote connection of each type of instrument must be carried out through the platform provided by each manufacturer, which greatly complicates integration and analysis tasks.

Together, this solution not only meets regulatory and risk management requirements but also establishes a standard of good practice for the safe operation and proactive maintenance of critical infrastructures in mining. The experience gained in this project lays the foundation for replicating and scaling this monitoring model in other mining operations with similar characteristics and challenges, with the possibility of incorporating other types of instrumentation into the platform.