1. INTRODUCTION

A tailings dam is a mining infrastructure whose main objective is to recover water and store the remaining solids from the mineral treatment. The water is collected for processing and reuse, while the solids, consisting of economically worthless milled ore, are generally deposited there.

The integrity of these dams is threatened by various risks, the most frequent being water seepage into the structure or natural events that exceed construction forecasts, thereby increasing the risk of rupture and consequent damage to property, people, and the environment downstream.

To mitigate these risks, it is necessary to use piezometers and accelerometers to permanently monitor water levels in slopes and the occurrence of earthquakes in the area.

2. INSTRUMENTATION AND MONITORING PROCESS

An instrumentation and monitoring project for a dam typically involves the following stages:

- Specification of instrumentation requirements.

- Monitoring system engineering.

- Provision of instrumentation and equipment.

- Instrumentation installation.

- Acquisition system installation.

- Installation of data transmission, storage, and visualization systems.

- System commissioning and training.

2.1 SPECIFICATION OF INSTRUMENTATION REQUIREMENTS

Usually, the Operation, Maintenance, and Surveillance Manual of a dam specifies the geotechnical instrumentation requirements for all projected stages of its useful life.

2.2 MONITORING SYSTEM ENGINEERING

Based on the mentioned requirements, all the equipment for the implementation of the monitoring system is selected. The characteristics of the required instruments are specified along with the dataloggers to be used for their acquisition.

According to the site’s characteristics, the appropriate power supply systems, grounding and lightning protection, data transmission network, and software hosted in the cloud or on own servers will be designed.

During this stage, all the necessary documentation for the provision of the equipment and its installation (material lists, procedures) is prepared. The software required by the dataloggers for data acquisition and transmission is also developed.

2.3 PROVISION OF INSTRUMENTATION AND EQUIPMENT

During this stage, GIEGROUP manages the acquisition, transportation, and nationalization of the required instruments and equipment.

For geotechnical instrumentation (piezometers, inclinometers, etc.), GIEGROUP represents the manufacturer Durham Geo Slope Indicator (DGSI). Accelerographs provided by Kinemetrics are used. For acquisition systems, those provided by Campbell Scientific are used.

2.4 INSTRUMENTATION INSTALLATION

Before installing the instrumentation, acceptance tests are carried out on-site to verify their correct operation and calibration parameters.

GIEGROUP personnel supervise all the on-site installation work of the instrumentation according to the developed procedures.

2.4 ACQUISITION SYSTEM INSTALLATION

GIEGROUP personnel carry out the installation of the specified acquisition, power, protection, and communication systems.

2.5 INSTALLATION OF DATA TRANSMISSION, STORAGE, AND VISUALIZATION SYSTEMS

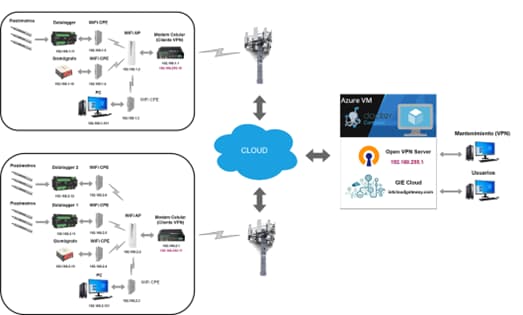

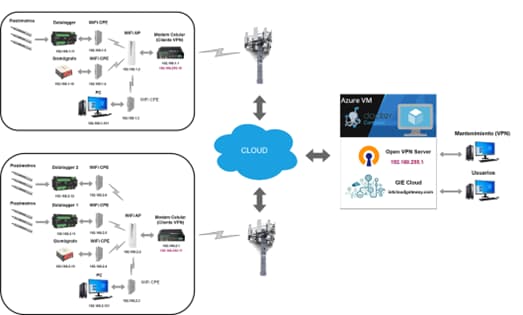

The data transmission system and access to the cloud/corporate network are designed during the engineering stage according to the site’s specific characteristics.

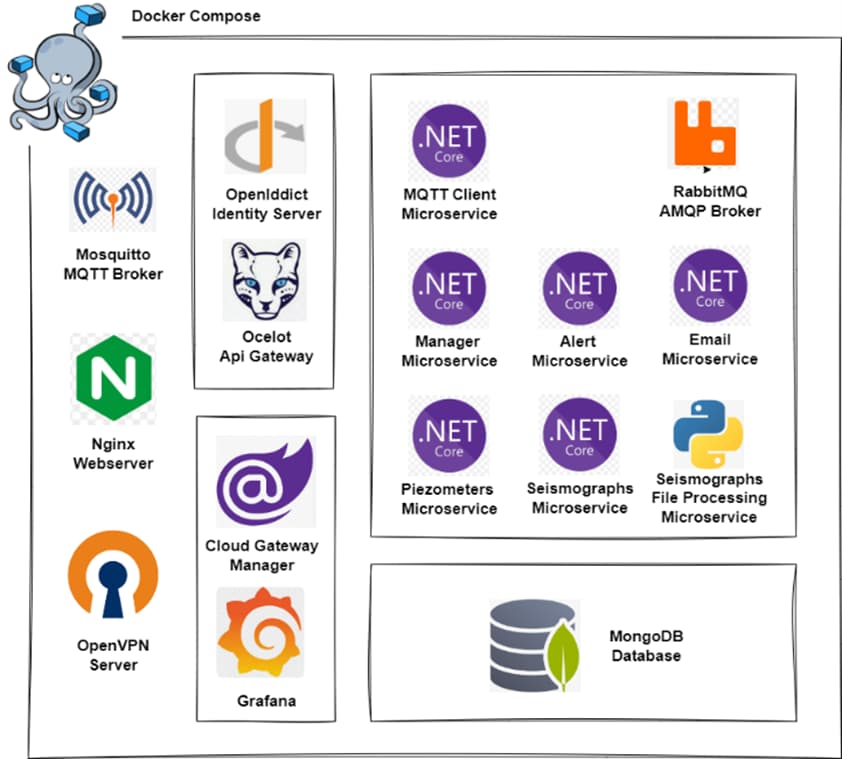

To expedite the development of solutions both for itself and its clients, GIEGROUP has developed its own IoT platform called Gie Cloud.

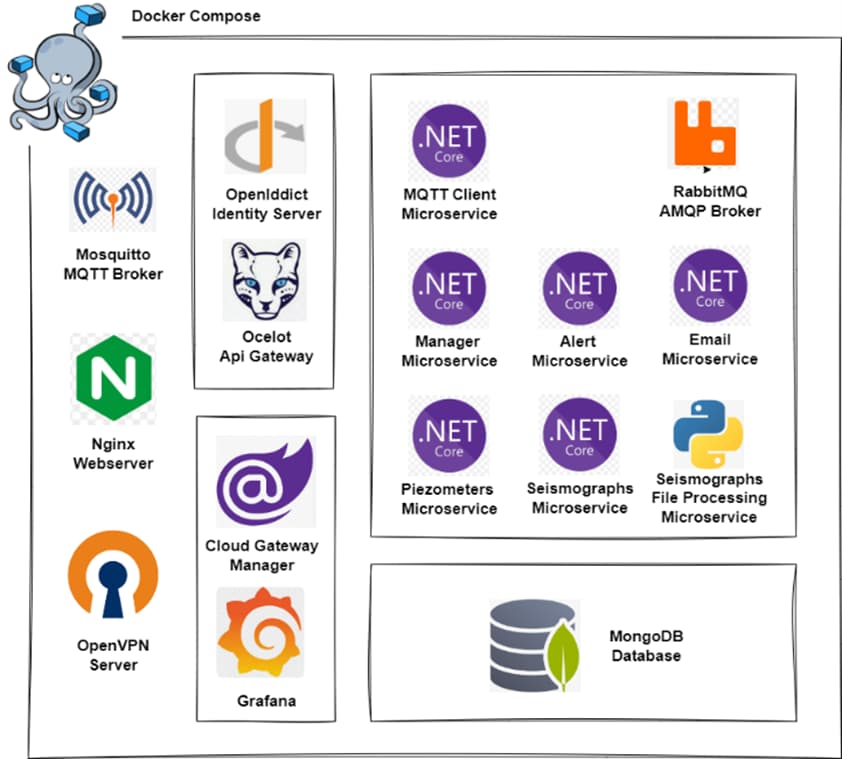

Based on microservices running in Docker containers, the platform is highly flexible to adapt and expand (new types of instruments/equipment) to the specific requirements of each solution to be implemented.

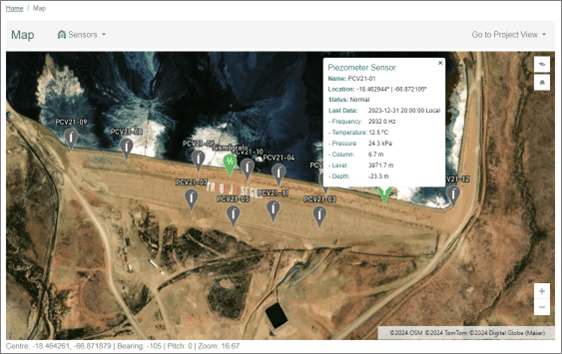

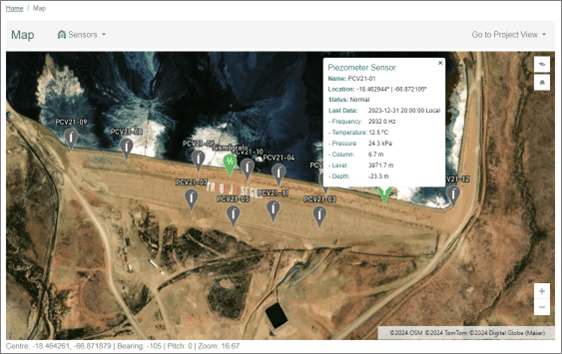

The platform allows the creation of new piezometers with their basic information, loading the configuration parameters that allow, based on the reported frequency and temperature, to calculate the pressure, column, and height in meters above sea level. It is also possible to set alerts on all these variables.

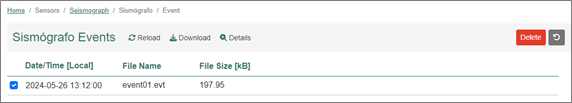

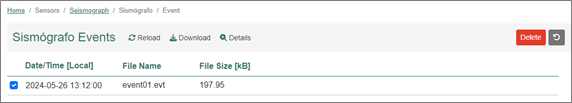

The platform allows the creation of new seismographs with their basic manufacturer and model information. It is also possible to set alerts to ensure connectivity and a key that must be loaded into the equipment itself to enable the recorded event files to be uploaded to the platform via HTTPS protocol.

2.6 SYSTEM COMMISSIONING AND TRAINING

During the system commissioning, the correct operation and visualization of the data received on the platform are verified.

During this stage, training on the use and maintenance of the platform is provided to the client’s designated personnel.

3. CONCLUSIONS

The geotechnical instrumentation and monitoring of tailings dams are crucial to ensuring the safety and stability of these mining infrastructures. The risks associated with possible water seepage or unexpected natural events underscore the importance of implementing a robust and continuous monitoring system.

Through a detailed process that includes the specification of requirements, system engineering, equipment provision and installation, and the implementation of advanced data acquisition and transmission systems, effective control of dam conditions is ensured. The IoT platform developed by GIEGROUP, Gie Cloud, exemplifies innovation in this field, allowing efficient and customized management of instrumentation and collected data.

Finally, adequate personnel training in the use and maintenance of these systems is essential to ensure safe and sustainable long-term operation. The combination of advanced technology, rigorous processes, and continuous training represents a comprehensive approach to risk mitigation and the protection of the environment and nearby communities.